|

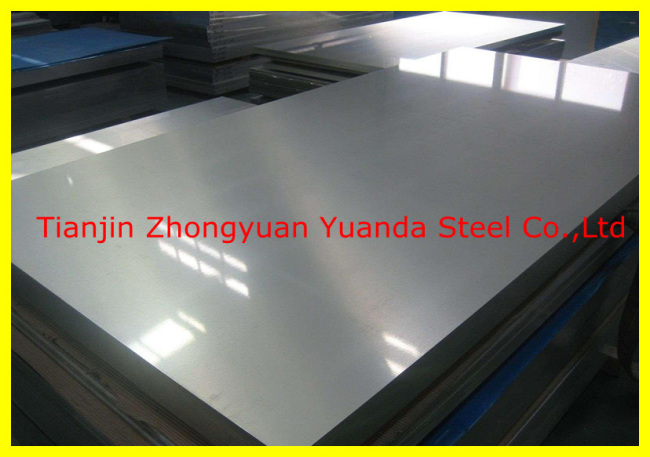

Tianjin Zhongyuanyuanda Steel Co.,Ltd.

|

430 Steel Sheet

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Type 430 Steel Sheet is the basic type in the ferritic group, possessing good ductility and excellent resistance to atmospheric corrosion.

Grade 201/202/304/316/430 Steel Sheet/sheets

However, Type 430 Steel Sheet is suitable for interior architectural and decorative household appliances trim as well as automotive body molding. Cold rolled Type 430 Steel Sheet has an attractive bright finish which can be maintained with reasonable care and periodic cleaning. Type 430 Steel Sheet is by far the most popular of all straight chromium stainless steels.

Specifications

Type: | 430 Steel Sheet | |

Trademark: | TISCO, BAOSTEEL | |

Standard: | ASTM, AISI, IS, DIN, EN, UNS, CNS, BS, KS, etc | |

Material: | 201,202,301,303,304,304L,316,316L,309,309S,310S,317L,321,409,409L,410,420,430 | |

Surface Finish: | 2B,Ba,HL,4K,6K,8K,Mirror,No.1,No.2,No.4,No.5,Wire Drawing | |

Size: | Thickness: | 0.3mm~100mm,or as customers' option |

Length: | 100mm~200mm,or as customers' option | |

Width: | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm | |

Shipment Terms: | FOB & CFR & CIF | |

Terms of Payment: | T/T:(30% T/T in advance,the balance against B/L copy) | |

Delivery Time: | Normally according to the order quantity | |

Technique: | Hot rolled,Cold rolled | |

Inspection: | Customer or The third party | |

Packing: | Paper interleave,fixed with fumigated pallet | |

Application: | Foodstuff, Gas, Metallurgy, Biology, Electron, Chemistry, Petroleum, Boiler, Nuclear energy, Medical equipment, Fertilizer etc. | |

The following specifications cover Stainless Steel 430

Principal Design Features:

A basic ferritic non-heat treatable stainless steel. Its strengths are in ductility, formability, good corrosion and oxidation resistance, thermal conductivity and finish quality.

Applications:

Appliance, automotive and architectural trim, vaults, heat exchangers, scientific apparatus and vending machine components.

Machinability:

Rated at 60 % of B1112. Relatively easily machined in all common procedures.

Forming:

Similar in forming characteristics to 304 stainless steel without the same degree of ductility. It does not, however, work harden greatly.

Welding:

All common welding methods used for stainless will be successful with 430. Filler metal should be AWS E/ER308 or 312.

Forging:

Bring the workpiece to 1500 F (816 C), then on quickly to 1900 F (1038 C). Prolonged exposure at this temperature will cause grain growth. Do not work this material at less than 1500 F (816 C). Air cool to room temperature and anneal.

Hot Working:

Generally the recommended method of hot forming is to work the material at between 1300 and 1500 F. Hot forming is only required on heavy sections.

Annealing:

Soak at 1500 F, furnace cool (50 F/hour) to 1100 F, then air cool.

Hardening:

430 does not respond to hardening by heat treatment.

Physical Data : [top]

Density (lb / cu. in.) 0.276

Specific Gravity 7.75

Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) 0.11

Electrical Resistivity (microhm-cm (at 68 Deg F)) 360

Melting Point (Deg F) 2750

Modulus of Elasticity Tension 29

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Stainless Steel 430

Steel Sheet

Sheet Steel

Sheet Stainless Steel

Corrugated Steel Sheet

Stainless Steel Sheet

More>>