|

Tianjin Zhongyuanyuanda Steel Co.,Ltd.

|

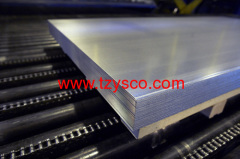

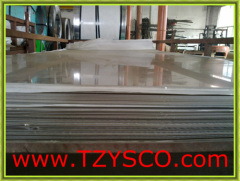

SS Sheets 316

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The application of ss sheets 316 is Foodstuff, Gas, Metallurgy, Biology, Electron, Chemistry, Petroleum, Boiler, Nuclear energy, Medical equipment,

SURFACE no.1/no.2/hl/ba/mirror //SS Sheets 316// Manufacture+Promotion

1.The main information:

2.The others about the SURFACE FINISH:

With the state-of-the-art production facilities, SS Sheets 316 is manufactured to meet the highest level of customers' requirements and underwent strict quality control before dispatch. The production facilities of SS Sheets 316 include 20 high sendzimir mill, bright annealing line, skin pass mill, tension levelling line, precision slitting line, and cut-to-length line. The SS Sheets 316 can be manufactured to various types of products with different grades, tempers, gauges, and specifications.

1.The main information:

Shipment Terms: | FOB & CFR & CIF |

Terms of Payment: | T/T:(30% T/T in advance,the balance against B/L copy)+L/C:100% irrevacable L/C at sight——the opened bank should be the first class |

Delivery Time: | Normally according to the order quantity |

Application: | Foodstuff, Gas, Metallurgy, Biology, Electron, Chemistry, Petroleum, Boiler, Nuclear energy, Medical equipment, Fertilizer etc. |

2.The others about the SURFACE FINISH:

1) NO. 1 -After hot rolling, to do heat treatment, pickling or corresponding processing on products.

2)2D - Annealed and pickling finish, semi-matt silver-grey surface. D= Dull

3)2B - Skin passed finish, , 2D light rolling between highly polished rollers B= bright

4)BA- Bright heat treatment or bright annealed, the product are of high reflectance and gloss.

5)HL-Using appropriate abrasive to grind product continuously so as to make grinding grain in it.

6)8K-The product is continuous processed with 1000 # abrasive thus it is with high gloss and reflection properties.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!